Metal surfaces are susceptible to wear and tear over time. The effects of corrosion, dents, and scratches can significantly impact both the aesthetics and functionality of various metal objects, from cars to household appliances. However, there’s a remarkable solution that can breathe new life into damaged metal surfaces – metal putty filler. This powerful compound not only fills in the gaps and imperfections but also creates a smooth and solid foundation for further refinishing. In this article, we will explore the incredible capabilities of metal putty and how it can revive the appearance and durability of metal surfaces. Whether you’re a DIY enthusiast or a professional in the field, understanding the potential of metal putty filler is essential for achieving flawless metal repairs. So, let’s dive into the world of this remarkable product and unleash its power to transform damaged metal surfaces into pristine works of art.

Benefits of Metal Putty Filler

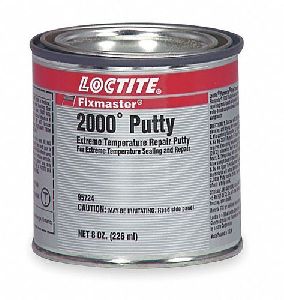

Metal putty filler is a game-changer for revitalizing metal surfaces. Whether you’re dealing with rusty or damaged metal, this incredible product offers a myriad of benefits that will leave you amazed. From repairing dents and scratches to restoring the original luster, metal putty filler is a must-have solution for any metalwork project.

First and foremost, one of the key advantages of metal putty filler is its versatility. It can be used on a wide range of metal surfaces, including steel, aluminum, and iron. This means you can use it for various applications, such as automotive repairs, DIY projects, or even industrial maintenance. No matter the type of metal, this filler is up to the task.

Another significant benefit is the ease of application. Metal putty filler typically comes in a convenient paste form that can be easily applied using a putty knife or spatula. This user-friendly nature makes it accessible for both professionals and beginners alike. With a little practice, you’ll find yourself achieving seamless results in no time.

Last but not least, metal putty filler provides long-lasting durability. Once applied and properly cured, it forms a strong bond with the metal surface, effectively sealing any imperfections. This durability ensures that your repaired metal will withstand the test of time, offering you a reliable and resilient solution.

In conclusion, the benefits of metal putty filler are undeniable. Its versatility, ease of application, and long-lasting durability make it an invaluable tool for anyone working with metal surfaces. So, next time you’re faced with a damaged or worn-out metal piece, don’t fret – unleash the power of metal putty filler and watch as it transforms your project into a masterpiece.

Application Techniques for Metal Putty

Metal putty, also known as metal putty filler, is a versatile material that can be used for a wide range of applications. Whether you need to fill in deep cavities, repair damaged metal surfaces, or create a smooth finish on metal objects, metal putty is the ideal solution.

Surface Preparation

Before applying metal putty, it is crucial to prepare the surface properly. Start by cleaning the metal surface with a degreaser or solvent to remove any dirt, oil, or grease. This step ensures that the metal putty adheres effectively to the surface and prevents it from peeling or cracking over time. Once the surface is clean, roughen it slightly using sandpaper or a wire brush. This will create a textured surface that enhances the bond between the metal putty and the metal substrate.Mixing the Metal Putty

Metal putty typically comes in two components that need to be mixed together before application. Follow the manufacturer’s instructions carefully to ensure the correct ratio of the components, as this will affect the final strength and performance of the metal putty. Use a clean mixing surface and a spatula to combine the components thoroughly until you achieve a uniform color and consistency.Applying the Metal Putty

Once the metal putty is mixed, it is ready for application. Use a putty knife or a similar tool to spread the putty evenly over the targeted area. Apply the metal putty in thin layers, building up the thickness gradually if needed. Ensure that the putty covers the entire surface and blends seamlessly with the surrounding metal. Smooth out any excess putty using the putty knife to achieve a smooth and finished appearance. Allow the putty to cure according to the manufacturer’s instructions before further sanding, painting, or finishing the surface if required.

epoxy putty singapore

By following these application techniques for metal putty, you can unlock the power of this remarkable material and achieve professional results in your metal restoration or repair projects. Remember to always wear appropriate safety gear and consult the manufacturer’s guidelines for any specific instructions or precautions related to the particular metal putty product you are using.

Tips for Achieving Long-lasting Results

Preparing the Surface: Before applying metal putty filler, it is crucial to prepare the surface properly. Begin by cleaning the metal surface thoroughly to remove any dirt, grease, or rust. This can be done using a degreaser or a mild detergent, followed by a gentle scrub with a brush. Once clean, rinse the surface with water and allow it to dry completely. This ensures that the putty adheres well and provides a durable finish.

Apply in Thin Layers: When applying metal putty filler, it is best to work in thin layers rather than applying a thick coat all at once. Thin layers allow for better control and minimize the risk of air bubbles or uneven drying. Start by applying a thin coat of putty using a putty knife or applicator, spreading it evenly over the damaged area. Allow each layer to dry completely before applying the next, following the manufacturer’s recommended drying time.

Sanding and Finishing: Once the putty has dried and cured, it is essential to smooth and finish the surface for a seamless and long-lasting result. Begin by gently sanding the dried putty using fine-grit sandpaper in a circular motion. This helps to remove any excess putty and create a smooth surface. Gradually increase the grit size to achieve a finer finish. After sanding, wipe away any dust or debris and examine the surface for any imperfections. If needed, apply another thin layer of putty to fill in any remaining gaps or low spots before repeating the sanding process. Finally, finish the surface by applying a suitable primer or paint, ensuring compatibility with the metal putty filler for optimal adhesion and longevity.

Follow these tips to achieve long-lasting results with metal putty filler, ensuring that your metal surfaces regain their strength and durability. Remember to always use the product as directed by the manufacturer and take proper safety precautions when handling chemicals and tools. With the power of metal putty filler, you can revive and restore even the most damaged metal surfaces.