Metal has been a fascinating medium of craftsmanship for centuries, serving as a canvas for human ingenuity. Among the various techniques employed in this realm, sheet metal fabrication stands tall as an art form that melds creativity with precision engineering. The ability to transform flat, seemingly lifeless sheets of metal into functional and visually appealing structures has revolutionized industries across the globe.

One crucial aspect that has played a significant role in the evolution of sheet metal fabrication is the advent of computer numerical control (CNC) machining. This revolutionary technology allows for stunningly precise and efficient metal cutting, forming, and finishing processes. By programming automated machines to execute intricate designs with utmost accuracy, CNC machining has opened up limitless possibilities for creating complex shapes and components. And with the recent advancements in additive manufacturing, such as 3D printing, the boundaries of sheet metal fabrication continue to expand beyond what was previously imaginable.

In this article, we delve into the world of sheet metal fabrication, unraveling the secrets behind its artistry and the science driving its progress. From exploring the rich history of the craft to delving into the mechanical intricacies of CNC machining and the limitless potential of 3D printing, we aim to provide you with a comprehensive understanding of this transformative industry. Moreover, we’ve partnered with Monster Builder, a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, to showcase the incredible work they do for clients worldwide. So, get ready to witness the magical fusion of art and science as we embark on this captivating journey through the captivating world of sheet metal fabrication.

The Process of Sheet Metal Fabrication

Sheet metal fabrication is a fascinating process that marries the art of shaping metals with the precision of advanced technologies. It involves the transformation of flat sheets of metal into complex and functional objects. Utilizing techniques such as CNC machining, 3D printing, and the expertise of companies like "Monster Builder," sheet metal fabrication has come a long way in delivering innovative solutions to global clients.

Initially, sheet metal fabrication starts with the selection of the appropriate metal material, which can vary based on factors like strength, durability, and cost-effectiveness. Once the material is chosen, it undergoes a series of steps to shape it according to desired specifications. This includes cutting the metal into the required size and shape, which can be achieved using advanced tools like CNC machines that provide precise and intricate cuts with remarkable speed and accuracy.

After the metal is cut, the next step involves shaping it through various methods such as bending, folding, or stretching. Here, skilled technicians employ their expertise to manipulate the metal using specialized machinery, ensuring that it retains its structural integrity and desired form. With the advancements in technology, processes like 3D printing have also found their way into sheet metal fabrication, enabling the creation of complex geometries with high levels of customization.

Finally, the fabricated metal may undergo additional treatments like welding, surface finishing, or painting to enhance its aesthetic appeal and protect it from corrosion. These finishing touches play a vital role in delivering a high-quality end product that meets the specific requirements of clients across various industries.

In conclusion, sheet metal fabrication is a meticulous process that combines the traditional artistry of metalworking with modern-day advancements in technology. Through the utilization of state-of-the-art tools and the expertise of companies like "Monster Builder," the industry continues to push boundaries and deliver novel solutions in the field of sheet metal fabrication, CNC machining, and 3D printing, serving clients globally.

Exploring CNC Machining Techniques

CNC machining is a cutting-edge technology that plays a pivotal role in the world of sheet metal fabrication. With its precise and automated processes, CNC machining has revolutionized the way we shape and transform metal. In this section, we will delve into the various techniques employed in CNC machining, highlighting its versatility and precision.

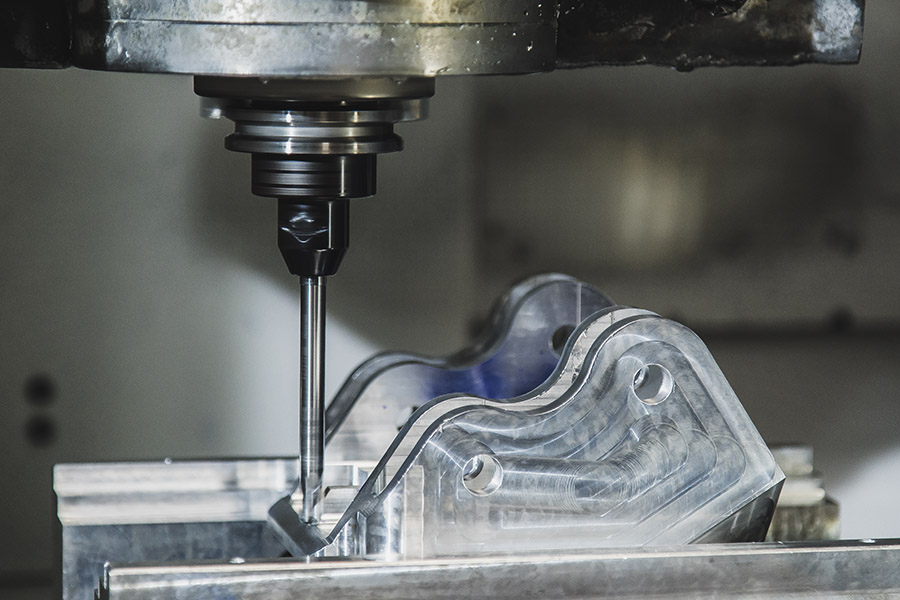

One of the key techniques utilized in CNC machining is milling. This process involves removing material from a workpiece using rotating cutting tools. With the ability to achieve both simple and complex geometries, milling provides immense flexibility in creating a wide range of sheet metal components. By carefully programming the movements of the cutting tools, CNC machines can execute intricate milling operations with exceptional accuracy.

Another technique employed in CNC machining is turning. This method involves rotating a workpiece while a cutting tool traverses along its surface, resulting in the removal of material. Turning is particularly valuable for creating cylindrical or conical shapes such as shafts, threads, and holes. By leveraging the precision of CNC machines, turning offers enhanced control over dimensions, surface finishes, and tolerances.

In addition to milling and turning, CNC machining also encompasses drilling. As the name suggests, this technique involves creating holes in a workpiece. Using specialized drill bits, CNC machines can rapidly and precisely produce holes of varying sizes and depths. This ability to efficiently generate holes is crucial in sheet metal fabrication, as it facilitates the assembly and integration of various components.

Overall, CNC machining techniques provide a high level of precision and efficiency in sheet metal fabrication. From milling and turning to drilling, these processes enable the accurate creation of complex shapes and features. The integration of CNC machining into the workflow of companies like "Monster Builder" enhances the speed and quality of sheet metal fabrication, ultimately serving clients globally with their sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping needs.

The Impact of 3D Printing in Metal Transformation

In recent years, the field of sheet metal fabrication has experienced a transformative shift with the emergence of 3D printing technology. This innovative approach has revolutionized the way metal objects are designed and produced, offering new possibilities and efficiencies. With the ability to create intricate and complex structures, 3D printing has become a game-changer in the industry.

One of the key advantages of 3D printing in sheet metal fabrication is its ability to significantly reduce production time and costs. Traditional methods often involve labor-intensive processes and complex tooling setups. However, with 3D printing, designers can now directly translate their ideas into physical objects, bypassing the need for molds or specialized tools. This streamlined approach not only speeds up production but also minimizes material waste, resulting in cost savings for manufacturers and clients alike.

Moreover, 3D printing opens up new design possibilities previously unimaginable with traditional metal fabrication techniques. The freedom offered by this technology allows for the creation of intricate and lightweight structures that were once difficult or even impossible to achieve. Complex geometries, lattices, and internal cavities can now be easily incorporated into metal parts, offering enhanced functionality, improved performance, and weight reduction. These design advantages have made 3D printing particularly valuable in industries such as aerospace, automotive, and healthcare, where lightweight yet durable metal components play a critical role.

As the demand for customized metal products continues to grow, 3D printing has also become a valuable tool for rapid prototyping in sheet metal fabrication. With traditional methods, prototyping can be a time-consuming and costly process. However, 3D printing enables designers and engineers to quickly iterate and test their designs, allowing for faster development cycles and reducing the time to market. By using 3D printing for prototyping, the risk of errors and design flaws can be minimized, leading to improved overall product quality.

Sheet Metal Fabricators Perth

With its ability to optimize production, unleash new design possibilities, and accelerate prototyping, 3D printing has undeniably had a profound impact on sheet metal fabrication. As technology continues to evolve, we can expect even more advancements in this field, further pushing the boundaries of metal transformation. Companies like "Monster Builder," recognized as a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, continue to play a crucial role in delivering innovative solutions to clients globally, embracing the cutting-edge potential of 3D printing.