Are you tired of spending countless hours manually wrapping pallets with stretch wrap? Look no further! In this comprehensive guide, we will take you through everything you need to know about maximizing efficiency with a stretch wrapper. Whether you’re new to the world of pallet wrapping machines or looking to upgrade your current pallet wrapper, we’ve got you covered.

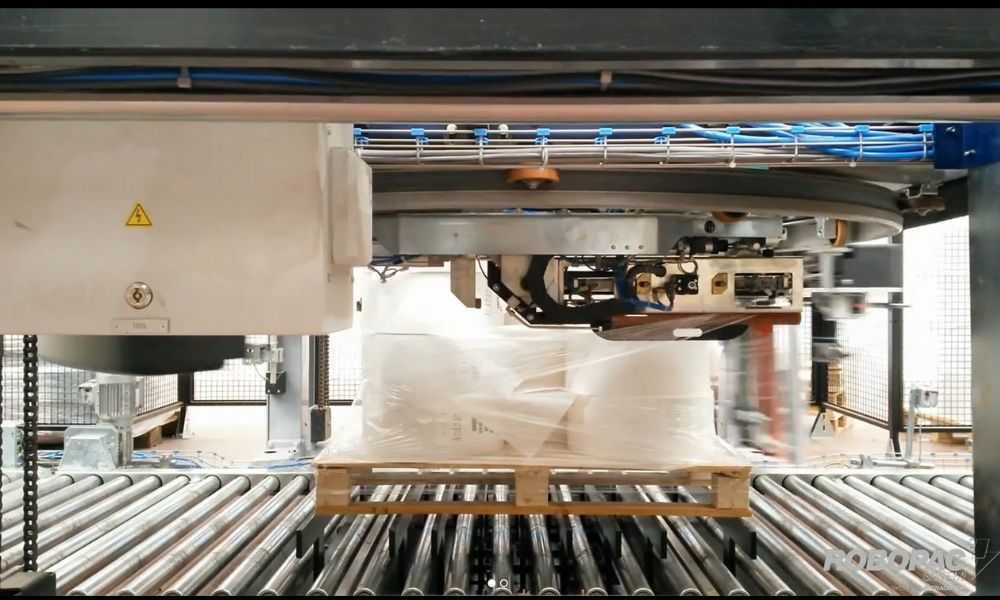

A stretch wrapper, also known as a stretch wrap machine or pallet wrapper, is a game-changer when it comes to packaging efficiency. By automating the pallet wrapping process, this innovative machine can save you time, effort, and money. Say goodbye to the tedious and labor-intensive task of manually stretch wrapping pallets, and say hello to a more streamlined and productive operation.

In the following sections, we will dive into the key features, benefits, and best practices of using a stretch wrapper. From understanding the different types of machines available to optimizing your stretch wrap settings for optimal results, we will provide you with practical tips and expert advice. Get ready to revolutionize your packaging process and maximize efficiency like never before with a stretch wrapper.

Benefits of Using a Stretch Wrapper

Increased Efficiency: Using a stretch wrapper, also known as a pallet wrapping machine or pallet wrapper, offers a wide range of benefits that ultimately lead to increased efficiency in your packaging process. By automatically wrapping pallet loads with stretch film, this machine eliminates the need for manual wrapping, saving valuable time and reducing labor costs. With its fast and consistent wrapping capabilities, a stretch wrapper can significantly speed up your packaging operations, allowing you to handle more pallets in less time.

Improved Load Stability: Another key benefit of utilizing a stretch wrapper is the enhanced load stability it provides. By securely wrapping the pallet load with stretch film, the machine ensures that the items on the pallet are tightly bound together. This prevents shifting, tipping, or any other form of movement during storage or transportation. The result is a more stable load that reduces the risk of damage to your products, making them less susceptible to potential accidents and improving overall product integrity.

Cost Savings: The use of a stretch wrap machine can also lead to substantial cost savings for your business. By precisely controlling the amount of stretch film used, the machine minimizes film waste and optimizes film usage. This reduces the cost associated with the consumables and contributes to a more sustainable packaging process. Additionally, the improved load stability mentioned earlier minimizes the risk of product damage, meaning less potential losses due to broken or damaged goods. Therefore, investing in a stretch wrapper not only increases efficiency but also helps save money in the long run.

In conclusion, the benefits of using a stretch wrapper, such as increased efficiency, improved load stability, and cost savings, make it an indispensable tool in optimizing your packaging operations. With its ability to streamline the wrapping process, enhance load stability, and reduce expenses, a stretch wrapper is a valuable asset for any business looking to maximize packaging efficiency.

Choosing the Right Pallet Wrapping Machine

When it comes to maximizing efficiency with a stretch wrapper, one of the key factors to consider is choosing the right pallet wrapping machine. With so many options available in the market today, it’s important to select a machine that meets your specific needs and requirements. Here are some factors to consider when making your decision.

Pallet WrapperMachine Capacity: The first consideration is the machine’s capacity. You need to determine the number of pallets you will be wrapping per hour or day and choose a machine that can handle that workload efficiently. It’s crucial to select a pallet wrapper that can keep up with your production demands to avoid any bottlenecks in your packaging process.

Film Compatibility: Another important aspect to consider is the type of stretch film that can be used with the machine. Different pallet wrappers may have limitations on the film thickness or width that they can accommodate. Ensure that the machine you choose can work with the stretch film options available to you, whether it’s standard, pre-stretched, or specialty films.

Features and Customization: Look for a pallet wrapping machine that offers the features and customization options that align with your specific needs. Depending on your requirements, you may need a machine with adjustable wrapping parameters, such as wrap tension, film overlap, or wrapping speed. Additionally, consider if you need a machine that can handle different pallet sizes or has the flexibility to wrap irregular-shaped loads.

By carefully considering these factors when choosing a pallet wrapping machine, you can ensure that you select the right machine to maximize efficiency and streamline your packaging operations. Remember to assess your current and future packaging requirements to make an informed decision that will benefit your business in the long run.

Best Practices for Maximizing Efficiency

Utilize Automatic Load Height Detection

One of the best practices for maximizing efficiency with a stretch wrapper is to make use of a pallet wrapping machine equipped with automatic load height detection. This feature allows the stretch wrapper to automatically detect the height of the load being wrapped, eliminating the need for manual adjustments. By eliminating the guesswork and time-consuming manual adjustments, this feature can significantly increase the overall efficiency of the wrapping process.Optimize Film Pre-Stretching

Another key practice for maximizing efficiency is to optimize the film pre-stretching settings on the pallet wrapper. Film pre-stretching involves stretching the film before it is applied to the load, allowing for greater coverage with less material. By properly adjusting the pre-stretch settings, you can ensure that the film is stretched to an optimal level, reducing the amount of film used while maintaining load stability. This not only increases efficiency by reducing material costs but also minimizes the need for frequent film roll changes.Regular Maintenance and Calibration

Lastly, regular maintenance and calibration are crucial when it comes to maximizing the efficiency of a stretch wrap machine. Routine maintenance, such as cleaning and lubricating key components, can help prevent breakdowns and ensure optimal performance. Additionally, calibrating the machine regularly ensures that it is operating at its maximum efficiency, resulting in consistent and reliable wrapping. By staying on top of maintenance and calibration, you can minimize downtime and keep your stretch wrapper operating at its best.

In conclusion, by implementing these best practices for maximizing efficiency with a stretch wrapper, you can streamline your pallet wrapping process, reduce costs, and improve productivity. Whether it’s leveraging automatic load height detection, optimizing film pre-stretching, or maintaining and calibrating the machine, these practices will help you get the most out of your stretch wrap equipment.